Year: 2016

How to cut an Iron Sleek Poly Steel Board

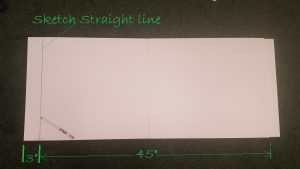

Step 5: With the board panels already marked and the steel channels already marked. Disassemble the channels from the boards.

Step 6: Cut the marked panel with a circular saw using a wood cutting blade. For best results you can use a table saw.

Step 7: Cut the 2 marked rails with a reciprocating saw, chop saw, or hand hack saw.

Step 8: After all the pieces are cut, you can chamfer or route cut edge of poly panel and file off sharp corners on the cut edge on steel channel.

Step 9:Now simply reassemble board components. Be sure to not spin out black mounting screws when reassembling. Your board should be your desired length. For this example it will be 45″

Check out this basement shooting lane. With the this ability to cut we were able to wrap around our customers basement to optimize the provided space.

Backyard Rink, Time to tear it down for Spring!

There are 2 reasons to hold off on draining your water. First, exposed water on a rink picks up kinetic energy from the wind to instigate the melt down. This makes a huge difference. Moving water melts ice so puddles on top of your ice will help to melt it, even at night. Keep the water in the rink. Second, the water temperature will rise faster than the ice temperature. Ice gets stuck at 32°F until it gains enough heat to convert to water.

This is the only time your white Iron Sleek liner is going to work against you. Since you have already had a season as manager of your rink, you know quite well that a leaf burns its way to the bottom of a rink. Consider placing a dark colored tarp on ice sections to gain solar energy.

The best way to remove water is with an electric or gas pump that has a discharge hose. Your local home improvement store usually rents them out. As a reference point, a 30 GPM pump will empty a 20×46 rink in 2-3 hours. With a pump arrangement, you have full freedom to direct the water to areas that are suited for drainage…like the city sewer. If you cannot reach the city sewer, you will need to direct the water toward a safe and convenient draining area.

Siphoning is slow but it works well. With siphoning, you will have some flexibility on directing the drainage. My warnings are that it will take several hoses to get a decent flow and that starting the suction takes some strong lungs. A benefit of siphoning is that the low flow rate gives the ground a better chance to absorb the water.

At the high water corner you can open your rink to let all of the water flow out. This is the fastest way to drain your rink. I have done it this way for years, but I did notice that is has some negative effects. Over flooding the grass can damage the grass roots. Also, repeated flooding can lower your ground’s grade.

If you need a piece of liner to cover your lumber, now is the time to cut that piece out.

Click here to read blog on rink improvements for spring.