An awesome feature of the Iron Sleek Poly Steel board systemis that boards can be cut in the field by our customers to custom fit their project requirements. This is a very unique capability that is easily accomplished with our board system. It is very useful for rinks that have borders or for optimizing size in a backyard. Below is a description on how to cut an Iron Sleek poly steel rink board to your desired length.

Iron Sleek Poly Steel Boards are standard 48” long from the lap joint edge to the board edge. It is very important to understand that the lap joint is not part of the length of the boards. The lap joint section of the board should not be cut.

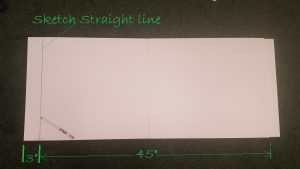

Step 1: Determine the target length of your board and make note of the deviation from the standard length of 48”. For example if the boards target length is 45”. The deviation is 48” minus 45” which equals a 3” deviation.

Step 2: Mark the deviation on the poly boards and the Poly Steel Channels before disassembling both opposite of lap joint.

Step 3: Sketch a straight cut line on poly panel.

Step 4: Mark the deviation on steel channel.

Be sure to mark both steel channels

Step 5: With the board panels already marked and the steel channels already marked. Disassemble the channels from the boards.

Step 6: Cut the marked panel with a circular saw using a wood cutting blade. For best results you can use a table saw.

Step 7: Cut the 2 marked rails with a reciprocating saw, chop saw, or hand hack saw.

Step 8: After all the pieces are cut, you can chamfer or route cut edge of poly panel and file off sharp corners on the cut edge on steel channel.

Step 9:Now simply reassemble board components. Be sure to not spin out black mounting screws when reassembling. Your board should be your desired length. For this example it will be 45″

Check out this basement shooting lane. With the this ability to cut we were able to wrap around our customers basement to optimize the provided space.